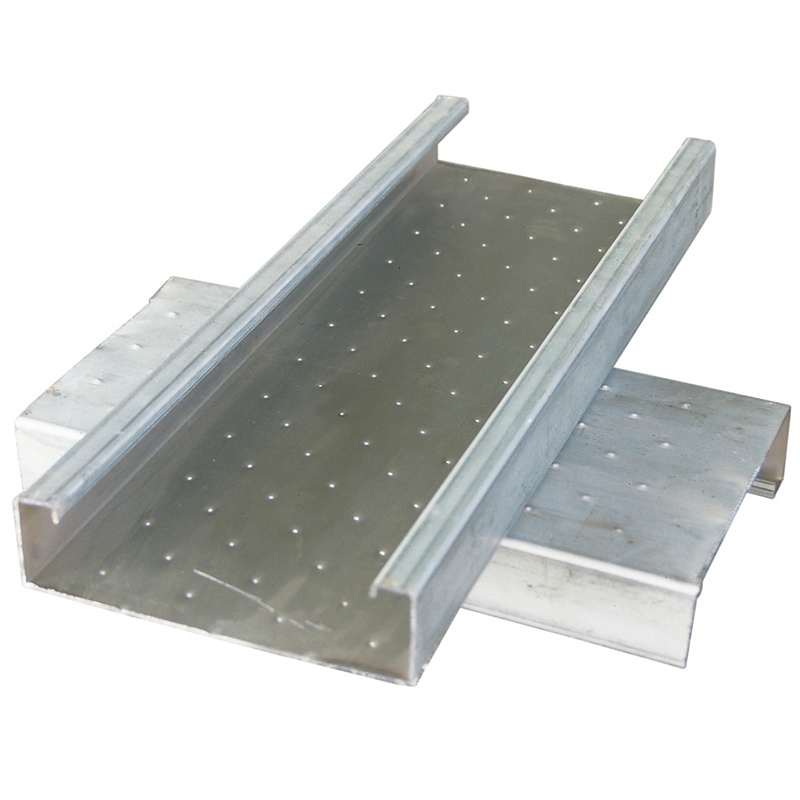

C channel is automatically processed and formed by a C channel steel forming machine. The C channel steel forming machine can automatically complete the forming process of the C channel steel according to the given C channel steel size.

Process for C channel

Unloading ①——Leveling ②——Forming ③——Sizing ④——Straightening ⑤——Measuring length ⑥——Punching round holes for tie bars ⑦——Punching elliptical connection holes ⑧——Forming and cutting ⑨

Type of C channel

Galvanized C channel steel, hot-dip galvanized C channel steel for cable tray, C channel steel for glass card groove, C channel steel for glass curtain wall, C channel steel for wiring trough, reinforced C channel steel, double-clad C channel steel , single-sided C channel steel, C channel steel for manual forklift, Unequal C channel steel, straight C channel steel, beveled C channel steel, inner curled C channel steel, inner beveled C channel steel, roof (wall) purlin C channel steel , automobile profile C channel steel, expressway column C channel steel, solar bracket C channel steel (21-80 series), formwork support C channel steel, precision C channel steel for equipment, etc.

Specifications/Technical parameters

FAQ

- Q: What’s your payment terms and delivery time?

A: 30% payment by T/T is required as deposit within ten (10) business days since the contract signing date. 70% balance payment is required by T/T prior to shipment. The delivery time for standard machine in 30 days, customized machine in 90 days to 120 days. - Q : Do you make for custom roll forming machine ?

A : Yes, most of our machines are designed and manufactured by custom demand, which the solution is discussed and approved by both parties. - Q : Are you a manufacturer or trader?

A: We are the original manufacturer.