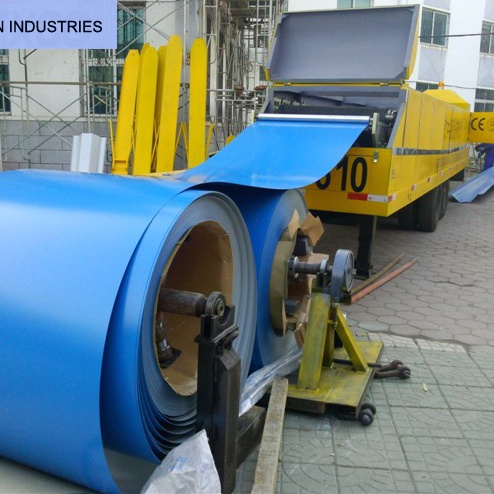

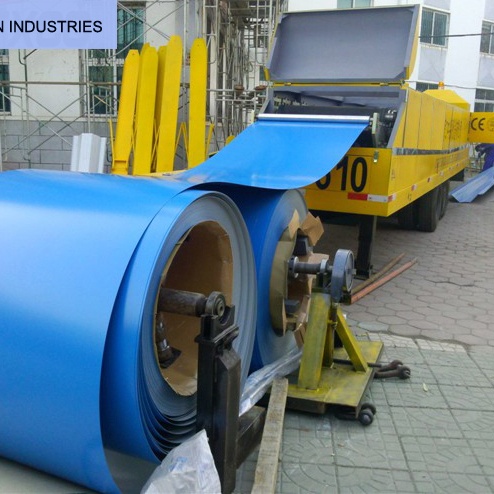

K Span Roll Forming Machine Attributes:

- Versatility: The K Span Roll Forming Machine is renowned for its versatility in producing a variety of panel profiles. It can efficiently handle different materials and thicknesses, making it suitable for diverse construction applications.

- High-Speed Production:

One of the key attributes of this machine is its capability for high-speed production. It is designed to deliver rapid roll forming processes, contributing to increased efficiency and reduced production time. - Precision and Consistency:

The machine is equipped with advanced technology to ensure precision and consistency in the forming of panels. This attribute is crucial for achieving uniformity in the final products, meeting quality standards. - Customization Options:

K Span Roll Forming Machines often come with customization features, allowing users to adjust settings for different panel dimensions and specifications. This flexibility caters to the unique requirements of various construction projects. - Ease of Operation:

Designed with user-friendly controls and interfaces, the machine offers ease of operation. This attribute is beneficial for operators, reducing the learning curve and enhancing overall productivity. - Durable Construction:

The machine is built with durability in mind, featuring robust construction and high-quality materials. This attribute ensures a longer lifespan and resistance to wear and tear in demanding working conditions. - Energy Efficiency:

Many K Span Roll Forming Machines incorporate energy-efficient technologies, contributing to reduced energy consumption during the manufacturing process. This aligns with sustainability goals and cost-effectiveness. - Minimal Material Waste:

With precise forming capabilities, the machine helps minimize material waste during production. This attribute is economically advantageous and environmentally conscious. - Automated Operation:

Automation is a notable attribute, as these machines often feature automated processes, reducing the need for manual intervention. This contributes to enhanced safety and operational efficiency. - Compliance with Industry Standards:

K Span Roll Forming Machines adhere to industry standards and regulations, ensuring that the produced panels meet the required quality and safety specifications.

Understanding these attributes is essential for those considering the adoption of a K Span Roll Forming Machine, as it helps in evaluating its suitability for specific manufacturing needs and project requirements.

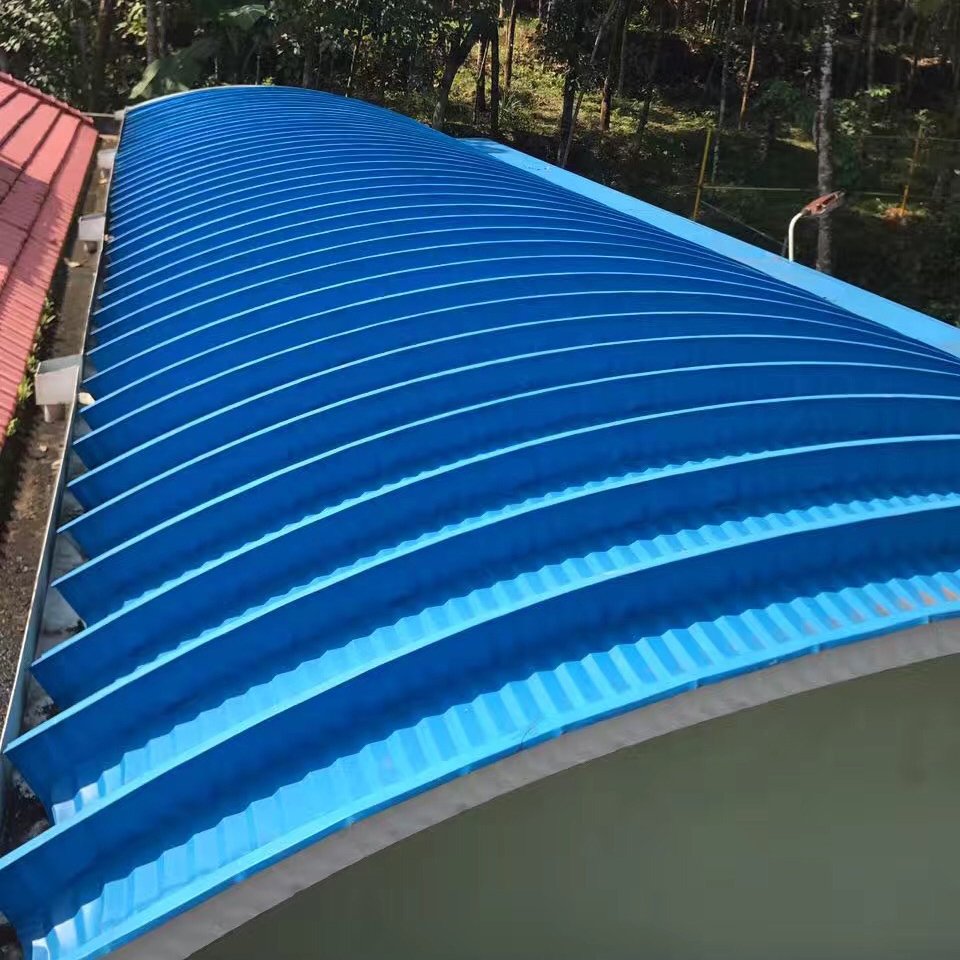

The K span arched steel roof is inspired by the structural shape of the skin texture of plants in nature. The thin steel plate is strengthened by corrugation to make a roof panel with a large span structure.

The role and requirements of K span arched steel roof:

The roof is the uppermost covering of the house, consisting of a roof and a supporting structure. The enclosure function of the roof is to prevent the invasion of natural rain, snow and wind and sand and the influence of solar radiation. On the other hand, it must bear the load on the upper part of the roof, including wind and snow load, the weight of the roof and the weight of possible components and people, and transmit it to the wall. Therefore, the requirements for the roof are strong and durable, light in weight, and have the properties of waterproof, fireproof, heat preservation and heat insulation. At the same time, it is required that the components are simple, convenient for construction and able to cooperate with the building as a whole, and have a good appearance.

Types of roofs: According to roof forms, they can be roughly divided into four categories: flat roofs, sloping roofs, curved roofs and multi-wave folded roofs.

Flat roof: The maximum slope of the roof does not exceed 10%, and the common slope of civil buildings is 1%-3%. Generally, cast-in-place and prefabricated reinforced concrete beams and slabs are used as the load-bearing structure, and the roof is treated with waterproofing and heat preservation.

Sloping roof: The roof slope is relatively large, more than 10%. There are various forms such as single slope, double slope, four slope and Xieshan. Single slopes are used for houses with small spans, while double slopes and four slopes are used for houses with larger spans. Roof trusses are often used as load-bearing structures, and tiles are used as roofs.

Curved roof: The shape of the roof is a variety of curved surfaces, such as spherical, hyperbolic paraboloid, etc. The load-bearing structure includes grid frame, reinforced concrete integral thin shell, suspension cable structure and so on.

Arched K span roof, commonly known as arched roof, beamless arch, space tile, due to its special structural form, many people are not very clear about its characteristics. Galaxy Steel Structure will introduce the beamless arch in detail. The main technical characteristics of the roof:

Technical feature 1: short construction period and excellent quality: advanced construction methods and scientific design concepts make the overall structure and node connections of the arched building with color plates reasonable and accurate. One piece of equipment can complete more than 600 square meters of color plate arched roof projects every day.

Technical feature 2: Low cost: The foundation structure of the arched building with color plates is simple, and the roof adopts the plate frame and arched groove plate, which eliminates the roof trusses and purlins in the traditional building form, and has a light weight. Compared with traditional buildings, the overall investment saving is about 30%.

Technical feature 3: beautiful shape and various varieties: the roof is arched, the facade can be designed at will, the interior space is open, can be separated and decorated freely, and the use is not restricted by the structure

Technical feature 4: Short design period: Refer to the US ASTM-77 light steel structure design code and follow the Chinese architectural design code, and its complete reliability meets the code requirements. According to the form, it can be designed on site, even if it is completed.

Technical Features

Technical feature 5: good thermal insulation performance: the current thermal insulation materials are polyurethane, fiber cotton and Audrin roofing materials, and the thermal insulation effect is excellent.

Technical feature 6: Long service life: It can be used permanently, and the color plate coating will not peel off or rust within 25 years of normal use.

Technical feature 7: High flexibility: no matter where the construction site is, the vehicle-mounted construction unit can quickly go to the site, and the self-powered equipment is a basically self-sufficient factory for producing houses. Colored galvanized steel, mechanical seam connection, natural waterproof, no leakage.