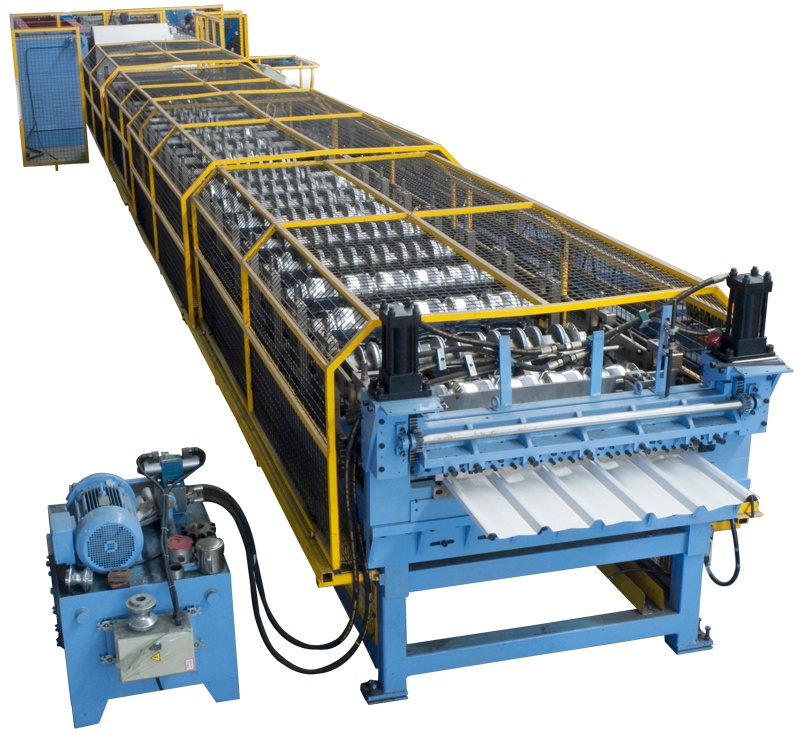

The Roof Sheet Making Machine stands as a pinnacle in modern manufacturing, seamlessly combining cutting-edge technology with efficiency and versatility. Crafted with precision, this machine boasts attributes that elevate it above the rest. Its high-quality materials ensure durability, while advanced technology allows for the production of a diverse range of roof sheets tailored to various specifications. The machine’s functionality is marked by precision engineering, enabling seamless operation and swift production. One of its standout advantages lies in its adaptability, accommodating customization needs and delivering a cost-effective solution for diverse roofing requirements. From its robust construction to its user-friendly features, the Roof Sheet Making Machine stands as an indispensable asset for those seeking reliability and innovation in the realm of roofing material production.

1. Introduction

Metal roof refers to the roof form that uses metal plate as the roof material and combines the structural layer and waterproof layer into one. There are many kinds of metal plates, including zinc plate, aluminum zinc plate, aluminum alloy plate, aluminum magnesium alloy plate, titanium alloy plate, copper plate, stainless steel plate, etc. The thickness is generally 0.4 ~ 1.5mm, and the surface of the plate is generally coated. Due to different materials and coating quality, the service life of some plates can reach more than 50 years. There are various shapes of plates, some are composite plates, that is, the insulation layer is compounded between two layers of metal plates, and some are single plates. During construction, some plates are assembled on site after being processed in the factory.

Our Roof Sheet Making Machine is a state-of-the-art solution designed for precision and efficiency in the production of roofing sheets. This advanced machinery seamlessly integrates into your manufacturing process, offering exceptional versatility and quality.

2. Key Features:

- Precision Engineering: Our Roof Sheet Making Machine is engineered with meticulous attention to detail, ensuring accurate and consistent profile shaping for each roofing sheet.

- Material Flexibility: This machine accommodates a variety of materials, including steel, aluminum, and more, providing flexibility in choosing the right material for your roofing sheets.

- Variable Speed Control: With adjustable speed settings, this machine allows you to optimize production based on your specific requirements, enhancing efficiency and minimizing material waste.

- User-Friendly Interface: The machine features an intuitive interface, making it easy for operators to set parameters, monitor the production process, and troubleshoot if necessary.

- Customizable Profiles: Tailor your roofing sheets to meet unique design specifications. Our machine supports the production of a wide range of profiles, allowing for creativity and customization.

- Robust Construction: Built with durability in mind, our Roof Sheet Making Machine is constructed from high-quality materials, ensuring longevity and reliability in demanding manufacturing environments.

- Price Competitiveness:

We understand that cost is a crucial factor in any manufacturing operation. Our Roof Sheet Making Machine is competitively priced, offering an excellent balance between affordability and advanced features. Contact us for a quote tailored to your specific needs. - Whether you’re a seasoned roofing sheet manufacturer or entering the industry, our Roof Sheet Making Machine provides the technology and reliability needed to elevate your production capabilities. Invest in quality, precision, and efficiency with our state-of-the-art machinery.

- Investment Value: Our Roof Sheet Making Machine not only excels in its technological capabilities but also proves to be a wise investment. The competitive roof sheet making machine price, coupled with its robust features, ensures that you get the optimal return on investment over the long term. This cost-effectiveness positions our machine as a valuable asset for businesses looking to enhance their roofing sheet manufacturing operations without breaking the bank.

- Scalability for Growth: As your business expands, our Roof Sheet Making Machine grows with you. Its scalable design allows for easy integration into larger production setups. The initial affordability of the machine, combined with its scalability, makes it an ideal choice for businesses planning for future growth and increased production capacity.

- Operational Efficiency: Reducing production costs and improving efficiency are paramount in the competitive manufacturing landscape. Our Roof Sheet Making Machine is engineered for operational efficiency, minimizing downtime and optimizing material usage. This operational effectiveness, paired with the reasonable roof sheet making machine price, ensures that you maintain a competitive edge in the market.

- Quality Assurance: Every roofing sheet produced by our machine is a testament to quality and precision. While our roof sheet making machine price is competitive, we never compromise on the excellence of the final product. The machine’s ability to consistently manufacture high-quality roofing sheets contributes to your reputation as a reliable supplier in the industry.

- Customization to Suit Your Needs: Understanding that every manufacturing process is unique, our Roof Sheet Making Machine offers a high degree of customization. Whether you require specific profile designs, material specifications, or production speed, our machine can be tailored to meet your exact needs. This adaptability ensures that you have the flexibility to address diverse market demands.

- Technical Support and Training: Purchasing our Roof Sheet Making Machine goes beyond the transaction. We provide comprehensive technical support and training to ensure that your team is well-equipped to operate and maintain the machinery. This commitment to customer satisfaction adds significant value to your investment, enhancing the overall ownership experience.

Our Roof Sheet Making Machine combines advanced technology, cost-effectiveness, and scalability, making it a strategic choice for businesses seeking a reliable and efficient solution. Contact us today to discuss your specific requirements and receive a personalized quote that aligns with your production goals and budget constraints.

3. Specifications/Technical parameters

|

5Ton X 1250mm Hydraulic Un-coiler |

Hydraulic system expand coil inner hole, Pump motor: 3KW Frequency Inverter to regulate turning speed, Motor: 3KW Coil Inner-diameter=510±30mm. Coil Outer-diameter Max. 1300mm; Taper wedge expanding system |

|

Entry roller & Manual Pre-shearing device |

Un-powered |

|

Cold Rolling Mills |

Feeding section with guide Gear/Sprocket driving;22-step to form Rollers manufactured from 45# steel, CNC lathes, hard Chrome Coated Shafts Diameter=ф75mm, Precision Machined Main motor =11KW, Frequency speed control Max. Line speed of roll former: 18~20m/min |

|

Hydraulic Cutting Device (two hydraulic cylinders) |

Stop to cut, Post cut, no blanking cut Hydraulic tank, Pump motor =4KW (Mounted inside of machine body) Cutting tool material : Cr12, Heat treatment;Mould steel with quenched treatment |

|

PLC Control System |

PLC (Siemens), Touch Screen (Siemens), Inverter (Schneider), Encoder (Omron), etc |

|

Simple product rack |

Un-powered, 3 units |

4. Product detail

1.Application: common building roof system, construction materials, stadium etc.

2.Original: Xiamen, China

3.Certification: ISO9001, CE etc.

4.Price: Negotiable

5.Voltage: 380V 50Hz, the voltage can be as local demand

6.Payment term: TT, LC

7.Delivery date: Negotiable

8.Packing: Naked package with poly wood case for control box

9.Market: ASEAN/Middle East/ South Asia/North America/Russia

10.Warranty: 1 year

5. Certificates

6. Our factory

Our factory was established in 2014, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, Meanwhile, we are the main drafter standard of China Non-standard roll former manufacturer and exporter of high quality roll forming machines in China. We are an ISO9001 approved company, and have European CE certification.

7. Advantage

1. we are the experienced factory

2. We can customize the machine according to your needs

3. easy to installation & Professional services

4. Integrity management: Our Company has established a long-term stable cooperative relationship with a number of manufacturers.

8. FAQ

1> How is your after-sales support?

We give 12 months of free warranty servicing and technical assistance after the equipment leaves the manufacturer. If the mechanical parts are still broken throughout the free warranty term, we can replace them with new ones at no cost.

2>What information must we provide before we can provide a quote plan?

You’ll need to know the thickness range, material specifications, and particular needs for equipment components.

3>What is the minimum amount of equipment that must be purchased?

a single set

9. EXHIBITIONS/MEETINGS

10. Direct Contact Information